|

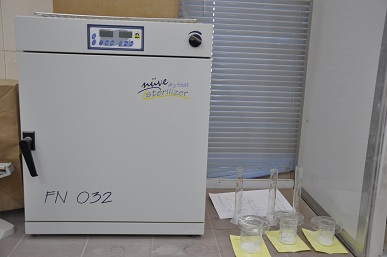

Dry heat sterilization is one of the earliest forms of sterilization practiced. Dry heat, as the name indicates, utilizes hot air that is either free from water vapour, or has very little of it, and where this moisture plays a minimal or no role in the process of sterilization. The Dry-Heat sterilization process is accomplished by conduction; that is where heat is absorbed by the exterior surface of an item and then passed inward to the next layer. Eventually, the entire item reaches the proper temperature needed to achieve sterilization. The proper time and temperature for Dry-Heat sterilization is 160 °C (320 °F) for 2 hours or 170 °C (340 °F) for 1 hour. Instruments should be dry before sterilization since water will interfere with the process. Dry-heat destroys microorganisms by causing coagulation of proteins. Se2The presence of moisture, such as in steam sterilization, significantly speeds up heat penetration.

|